Introduction: Revolutionizing Healthcare with 3D Printing

3D Printing in Medicine has emerged as a revolutionary technology for the health sciences, transforming patient care with unprecedented precision and personalization. The advent of additive manufacturing solutions for high-detail, adaptable, and personalized medical needs has opened new horizons in prosthetics, implants, surgical instruments, and artificial organs. Furthermore, its ability to reduce costs, save time, and improve patient outcomes solidifies medical 3D printing as one of the most promising innovations in modern healthcare. Ultimately, the continuous advancements in 3D printing technology for healthcare are shaping the future of medicine.

From improving mobility with custom prosthetics to addressing the organ donor shortage through bioprinting, this article explores how 3D printing is shaping the future of healthcare and overcoming some of its most pressing challenges.

What is 3D Printing in Healthcare?

Simply put, 3D printing is the process in which special machines add three-dimensional objects in successive layers.

In medicine, this technology enables the development of customized medical devices and models based on every patient’s unique topography or pathology.

Key Steps in 3D Printing for Healthcare:-

Digital Design: By means of such imaging modalities as CT scans or MRIs, the medical staff builds up a 3D digital reconstruction.

Material Selection: Depending on the application, materials such as polymers, metals, ceramics, or biological tissues are selected.

Printing Process: The use of the 3D printer results in the object being built layer by layer according to the digital model.

Post-Processing: The printed item undergoes cleaning, sterilization, or refinement before use.

This customizable approach has revolutionized patient care, allowing for solutions that were once considered impossible.

Custom Prosthetics: Enhancing Mobility and Quality of Life

Among the most effective applications of 3D printing in the medical field is the fabrication of one’s own prosthetics. Traditional prosthetics are often expensive and require multiple adjustments. 3D printing addresses these challenges by providing faster, more affordable, and personalized solutions.

Benefits of 3D-Printed Prosthetics: –

Personalization: Prostheses can be manufactured to the exact shape and size of a patient’s residual limb, resulting in enhanced comfort and function.

Affordability: The price of 3D-printed prostheses is much cheaper than conventional options and is therefore marketable to patients living in low-income settlements.

Faster Production: It takes several days instead of weeks or months to print a prosthetic.

Adaptability for Children: A growing child can easily grow out of a physical prosthesis, but 3D printing supports fast and cheap substitute parts.

Case Study: Prosthetics for Developing Nations

However, organizations such as e-NABLE and Open Bionics are using 3D printing to offer low-cost prostheses to children and adults who live in neglected communities. For example, a 3D-printed prosthetic hand costs as little as $50, while conventional models are significantly more expensive (thousands).

Implants and Surgical Tools: Precision and Customization

3D printing has also made significant strides in the production of implants and surgical tools, offering solutions tailored to individual patients.

Custom Implants

Three-dimensional (3D) printing allows the generation of patient-unique implants for bones, joints, and dentition applications. This precision reduces complications and improves outcomes.

Orthopedic Implants: Customized hip and knee replacements are created to fit perfectly, reducing the risk of implant failure.

Dental Implants: 3D-printed crowns and bridges are fabricated with such accuracy to match a patient’s teeth to a very high degree.

Cranial Implants: Three-dimensional (3D)-printed cranial plates are an anatomic fit for patients having head injury or deformity.

Surgical Tools

Surgeons can employ 3D printing for custom-made surgical instruments, e.g., for guidance of intricate procedures. These tools ensure greater accuracy and reduce surgery time.

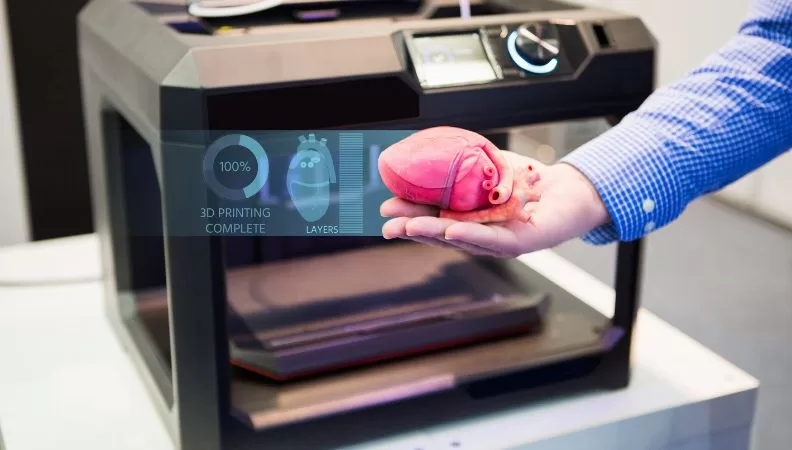

Bioprinting: The Future of Organ Replacement

Among the most exciting developments in 3D printing is bioprinting, which derives tissues and organs from living cells. This technology holds the power to resolve the organ shortage crisis in the world, through the elimination of the role of donors.

How Bioprinting Works: How Bioprinting Works:-

Cell Harvesting: Doctors take cells from the patient or a donor.

Bioink Preparation: Researchers suspend the cells in a gel-like material to produce “bioink.”

3D Printing: Researchers print bioink layer by layer and create the desired tissue or organ.

Maturation: Researchers then incubate the printed structure to facilitate cell growth and settling.

Applications of Bioprinting: –

Skin Tissue: Skin bioprinted is applied to burn patients and for cosmetic purposes.

Cartilage and Bone: Used for orthopedic and reconstructive surgeries.

Organs-on-Chips: Researchers employ model organ replicas for drug screening and research.

Full-Scale Organs: Although bioprinting functional organs are still in experimental form, the research team is moving towards the bioprinting of functional organs, such as kidneys, livers, and hearts.

Challenges in Bioprinting: Challenges in Bioprinting

Successful vascularization (angiogenesis) of large organs is a fundamental challenge.

Regulatory bodies and ethicists should first consider approvals and issues before the broad use of techniques.

Educational and Pre-Surgical Models

Furthermore, 3D printing is changing medical education and preoperative planning. Surgeons and students can replicate complex procedures in life-like anatomical models or gain an understanding of unusual patient anatomy in life-like anatomical models.

Advantages of 3D-Printed Models: –

Improved Surgical Outcomes: Physicians can practice surgical procedures using models of the patient’s anatomy, thus lessening risk during actual surgery.

Medical Training: Trainees can practice on realistic models without needing cadavers.

Cost-Effective Learning: 3D models are cheaper and more accessible to produce compared with conventional teaching aids.

Advancements in Materials for Medical 3D Printing

The application of 3D printing materials in healthcare is of paramount importance to the success of 3D printing. Recent advances have increased the number of biocompatible and functional materials available.

Common Materials in Medical 3D Printing: –

Polymers: Used for prosthetics and surgical models.

Metals: Titanium and cobalt-chrome are popular for orthopedic implants.

Ceramics: Ideal for dental applications and bone grafts.

Bioinks: Living cells mixed with hydrogels for bioprinting.

Developing materials, such as bioactive glass and biodegradable polymers, are facilitating novel sophisticated applications, e.g., tissue regeneration.

Challenges and Ethical Considerations

Although 3D printing has great potential, challenges, and ethical problems also exist.

High Costs of Advanced Equipment

While prices have gone down, however, top-tier 3D printers and materials are still costly for most healthcare professionals. Moreover, the high initial investment limits accessibility for smaller medical practices. In addition, ongoing maintenance and material costs add to the financial burden. Consequently, many healthcare providers are unable to adopt this technology at scale. Ultimately, finding ways to reduce these costs will be essential for wider adoption in the medical field.

Regulatory Hurdles

Researchers must prove the safety and effectiveness of 3D-printed medical devices with strict testing and approval.

Intellectual Property Concerns

The ability to replicate designs raises concerns about intellectual property theft and unauthorized usage.

Ethical Questions in Bioprinting

The development of living tissues and organs brings forth ethical challenges (e.g., cloning issues, and access problems).

Future of 3D Printing in Healthcare

The application of 3D printing in the health field is extremely promising, and moreover, it continues to evolve with ongoing research and innovation. In addition, these advancements further broaden its ability to apply across diverse medical areas. Consequently, 3D printing is now playing a pivotal role in creating patient-specific implants and prosthetics. Furthermore, its potential to revolutionize personalized medicine is becoming increasingly evident. Ultimately, the integration of this technology will significantly transform healthcare delivery.

Key Trends to Watch: –

Personalized Medicine: 3D printing will make customized treatments from implants to drug delivery tools possible.

On-Demand Printing: Portable 3D printers may enable on-site fabrication of medical devices from remote, disaster-prone regions.

Advancements in Bioprinting: Researchers are making efforts toward fully functional transplantable organs that may become available within the next 10 years.

Eco-Friendly Materials: The development of biodegradable and sustainable materials will make 3D printing more environmentally friendly.

Conclusion: Transforming Medicine with 3D Printing

As a result, 3D printing is transforming medicine by providing unprecedented capacity for personalization, accuracy, and innovation. From life-changing prosthetics to groundbreaking bioprinting, this technology is addressing critical challenges in patient care while opening doors to possibilities once thought impossible.

With further developments, 3D printing will serve as a crucial factor in tailoring healthcare for both accessibility and effectiveness, ultimately enhancing the lives of millions of patients all over the world.